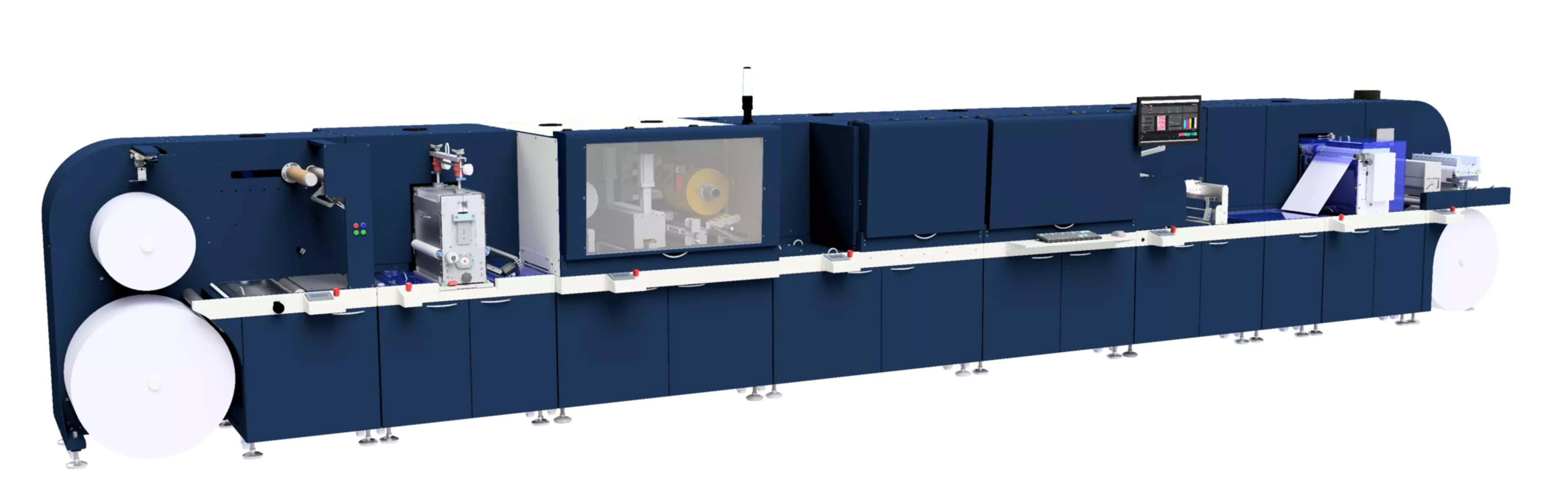

Printing Speeds | Up to 42m/mn¹ (depending on application). |

Supported Web Widths | From 100 mm up to 420 mm |

Finishing Width | The maximum image width is 405 mm |

Substrate Types² | From 50 up to 400 microns (μm)Coated, uncoated and textured paper, film or labelSelf-adhesive labelsWhite or transparent synthetics, PP, PE, POPP, PETLight cardboard/folding cartonShrink film: PVC, PETG |

Wide Compatibility | Compatible with the overall web-to-web printingTechnologies, narrow web digital presses and the traditional offset or flexo narrow web presses. |

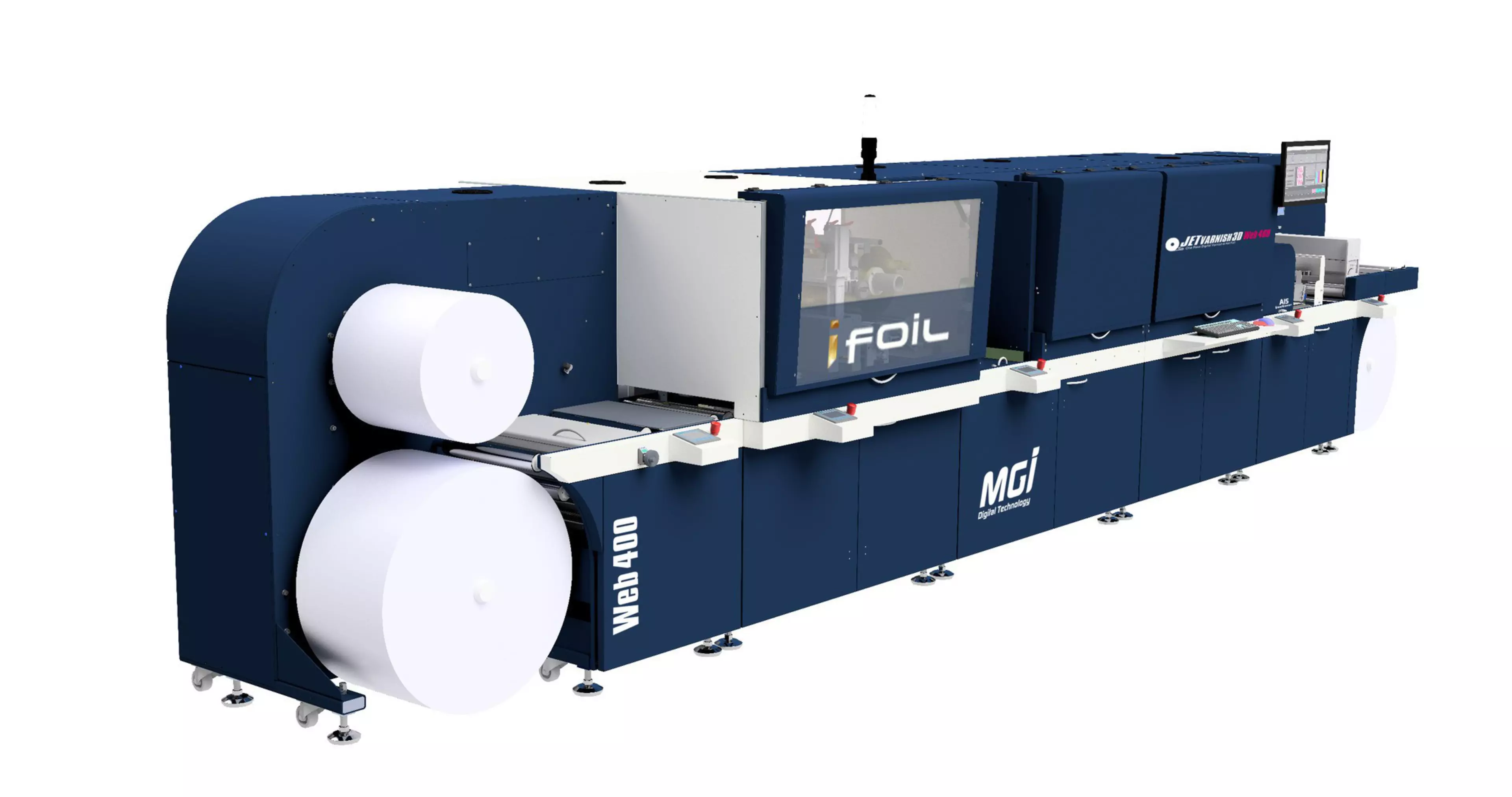

Unwinder | Maximum roll diameter capacity: 850 mmStandard inside core diameter: 3 inchesMaximum roll weight: ±120 kg |

UV Flexo Station | An integrated flexo station for full size sleeve coating in rotary. This station is used to apply a UV protection varnish or primer prior to finishing. The module comes with an UV dryer. The station is equipped with an anilox cylinder.Additional anilox cylinders are available as upgrade options. |

Spot UV Coating andEmbossing Station | This station uses MGI award-winning inkjet technology for producing Spot UV Coating. Any defined label area can receive Spot UV Coating with or without raised 3D texture effects. A simple grey level TIFF file designed by Prepress controls the surface area and the thickness of the varnish applied over the printed roll. This 100 % digital process eliminates traditional plates, screens and dies. |

Varnish thickness | From 7² to 232² μm of varnish thickness (from 2D flat coats to 3D raised effects). |

Inline curing | The unit is equipped with an UV dryer and a cooling drum for optimum web temperature control. The curing sequence also includes a special forward and backward roll motion to dry each label and eliminate waste between runs. |

UV Varnish | Gloss varnish 99 GU |

Hot Foiling Station | The hot foiling station adds luxurious effects and brand value to label and packaging products. Any defined label area can receive digitally-controlled foil with or without raised effects.A simple grey level TIF file designed by Prepress controls the surface area and the definition of the foil applied on the printed roll. This 100 % digital process eliminates traditional dies, plates and screens.Foil application can be bypassed when not necessary. |

Foil rolls | Foils are delivered on rolls:Foil widths from 100 mm up to 420 mmFoil roll core diameter: 1’’ and 3’’Foil lengths from 400 m up to 2,000 mUp to 3 rolls can be used simultaneously during the production |

Die Cutting Unit | A semi-rotary die cutting unit is available as an option to finish labels in-line on the JETvarnish 3DWeb. The unit uses a 21’’ magnetic cylinder and an automatic registering system. 2 slitter knives are included as well as a matrix rewinder.format in semi-rotary: 100 up to 480 mmmaximum matrix diameter: 600 mm2 slitter knives as standard: 10 maxGap master system for die height adjustment as an option. |

Rewinder | Servo-motorized unit850 mm maximum roll diameter capacityStandard inside core diameter: 3 inchesMaximum roll weight: ± 120 kg |

Printing PressCompatibility List | Digital: Konica Minolta AccurioLabel, HP Indigo WS4500, HPIndigo, WS6800, Epson, Xeikon, EFI, Durst, etc.Offset: All manufacturers and technologies: UV, H₂O orWATERLESSFlexo: All manufacturers and technologies: UV or Water based |

Dimensions & Weight | 400 V - 3Ph240 V - 1PhDry air compressor (oil-free): 8 bar/102 psi - 24 m³/h/6 cfmAll speeds are nominal |

Corona substratetreatment module | In-line system made to optimise varnish adhesion on complex printed substrates |

Variable Data Printing | To manage and edit files on the workstation,Full variable data (text, graphic, image) for both 2D/3D SpotCoating and Hot Foiling areas,Integrated barcode (1D/2D) reader system & controller,Raster Image Processor (RIP) as an option |